*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate, I earn from qualifying purchases. Please read my disclaimer for additional details.

If you are installing your own siding, you may reach a point (such as the corners of the home) where you have to bend the siding. Bending the siding on your own is a better alternative than trying to purchase siding that is already bent because you’ll pay a premium for the additional manufacturing process that went into it.

Bending siding without a brake is certainly doable since all you have to do is create your own, DIY brake, which really isn’t as hard as it sounds.

You can also get pretty innovative with 2x4s, without actually building a brake at all. These methods work best for steel, aluminum, and vinyl siding.

Keep in mind, that there are roughly 15 different types of siding and you can only bend a few of them. While vinyl is certainly on the list of bendable sidings, you should never attempt to bend vinyl in cold weather because it will snap in two at the pressure point.

Table of Contents

Why Would You Want to Bend Siding Without a Brake?

One of the biggest reasons that many people would run away from the idea of using a brake for bending their siding is because the things are insanely expensive.

This is compounded by the fact that purchasing a brake is on top of paying for a whole bunch of siding.

Just a brief look at this page , it will show you the extraordinary price for any one of the brakes by a large number of brands. Of course, that doesn’t include any of the extra accessories that you will need for the brake as well.

Another reason for bending siding without a brand-named, manufactured brake is that you can essentially design your own or find a variety of ways to create your own leverage to professionally and precisely bend siding.

You can either build your own brake, which is a far more cost-effective solution than purchasing one, or you can use several different tools right from your own toolbox to do the trick, especially if you have some metal or 2x4s laying around.

What Kind of Siding Can You Bend?

In general, the only kind of siding that you will be able to bend are metal and vinyl siding. There are a number of different kinds of siding materials out there but there are only a few that are conducive to being bent, curved, or otherwise warped out of their original shape.

The vinyl itself is a bit limited, especially if you are looking at intricate and multiple, small bends over a short surface area, which is sometimes required for certain areas of the house and is almost always required on the corners, where you not only need to bend the vinyl to cover the corner, but also to allow side panels to fit the corner panel.

When it comes to vinyl, too much of something is rarely a good thing. You also run into the problem of creating bright, white lines in the vinyl material, right where the bend is located.

If you are using really dark-colored vinyl, bending it by 45° or more may not be in your best interest.

Bending metal siding is far easier and you can bend it into multiple, complex shapes as needed.

The only drawback is that steel siding is quite resistant to bending without a brake, so you will need something that is pretty sturdy.

Aluminum siding, on the other hand, is far more ‘spring’ and flexible, making it more difficult to get achieve a precision bend that the aluminum doesn’t try to spring back out of.

Working with aluminum without a brake can be a challenge to get perfect.

How to Bend Sinding Without a Brake?

It’s okay to use 2x4s or other types of wood to bend vinyl, as it is softer and a little easier on the material when you are trying to bend it.

However, for bending metal siding, you want to use metal, since wood is just not hard enough to get the best and most precise bend in the siding material.

Prepping Vinyl

As we mentioned earlier in the article, if vinyl is cold, it is much more susceptible to snapping when you try to bend it past a certain angle.

Even if the vinyl that you are trying to bend is at room temperature, you still want to be very careful, especially since not all vinyl is created equally.

Fortunately, there is one way to ensure that the vinyl you are trying to bend doesn’t break and that’s to heat it up. To do this, you will want to use a heating gun or even a regular hair dryer will do the trick.

Simply heat it up by moving the hair dryer or heat gun up and down the vinyl, a couple of inches away from the material, in slow but not ridiculously slow sweeps.

It’s usually best to do this just before clamping it down but after you’ve set everything up, so you can bend it before it cools back down.

Vinyl can also be a little like aluminum when it’s not heated up. In other words, it will resist a precision bend and try to spring back out into its original shape.

Heating it up will make it more malleable and it will bend much easier.

Things You Will Need for Vinyl or Metal Siding

There are several things that you will need before you get started and much of it is preparatory material.

- Sharpie for marking your bends

- Metal ruler or square

- C-clamps

- Flat, heavy metal bars

- Hammer

- Flathead screwdriver

The sharpie is best for marking your bends, however, always make sure that the sharpie marks that you make are going to be on the inside of the bend.

You may think that you can paint over them but you would be surprised at how easily sharpie will bleed through even industrial paints.

The metal ruler and square are for making the most precise markings that you can while you will need multiple c-clamps to hold all of the material in place.

The flat metal bars need to be longer than the section of metal or vinyl that you are bending so that you have room to clamp.

The hammer and flathead screwdriver are for alternative methods of bending the metal.

Clamping and Bending Your Siding

You will need a work table of some sort or you can use two sawhorses situated opposite of each other with the length of the bars in between them.

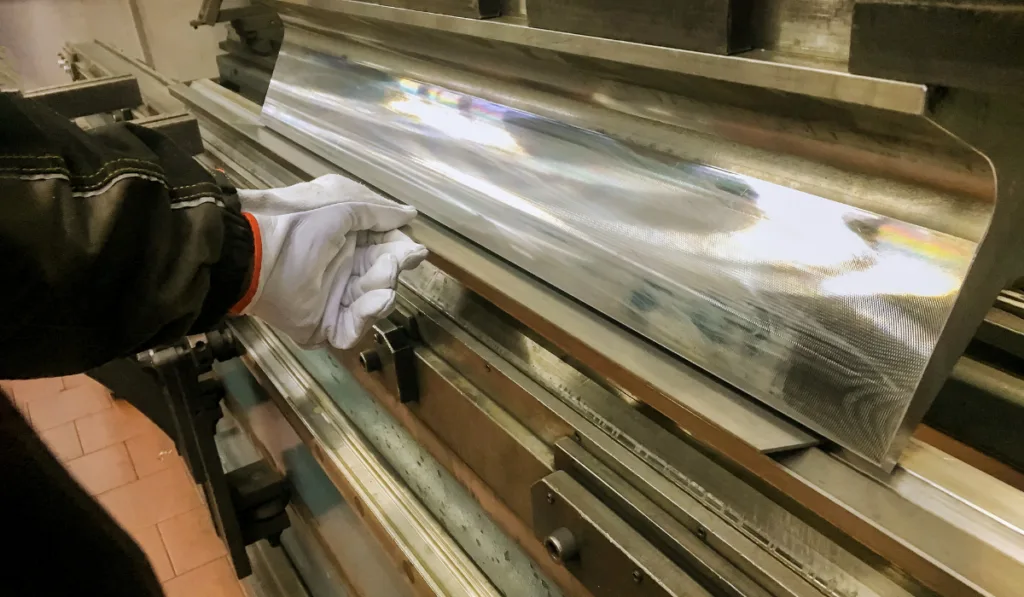

One steel flat bar is going to be on the bottom and you should c-clamp it hard to the sawhorses or worktable.

Take your second flat bar and lay it over the top of the first. You can place two more c-clamps to squeeze the two flat bars together but keep these two c-claps loose enough that you can slide your siding in between the two flat bars.

When you place your siding between the two flat bars, ensure that the straight line mark that you made for the bend is flush with where the two flat bars come together.

Once your siding is in place, c-clamp everything down really tight.

Now, you can approach this through one of three methods:

- Simply use your hands to fold the metal.

- Use your hands to fold it but add the use of a hammer to make the bend tighter.

- Scour your mark with the pointy corner of a flathead screwdriver.

Using Your Hands

Once the siding is in place, use one hand to start folding the siding.

Don’t grab the lip of the siding and push up. It’s better to place your palm flat on the bottom of the siding, with most of the upward pressure applied close to the bending point.

This way, you don’t curve the metal and you will be able to bend the whole section more precisely.

Using a Hammer

You do everything the same way with this method, however, once your bend is complete, you take an additional step with the hammer by gently tapping the metal close to the bend and towards the direction of the bend. This method is only viable with metal siding.

Scouring Metal Siding

This method, like the hammer, doesn’t work with vinyl and is only for use with metal siding. Once you make your mark with the sharpie, all you do is use the sharp corner of the flathead to scour the metal all the way down the line.

Dig in hard and ensure that there is a clear and straight channel entrenched in the metal. Don’t go too deep, as the integrity of the metal siding will be lost and it might break when you fold it.

After this, you fold the metal siding like normal.

All Things Considered

That’s really all there is to it. If you are trying to bend metal or vinyl siding without a brake, you have to create something long, flush and can hold the siding between them so that it can be properly bent.

Resources

Miller, N. (N/A) How to Bend Sheet Metal Without a Brake

Retrieved from: https://homesteady.com/12586994/how-to-clean-up-tarnish-on-goldtone-metal

How to Bend Sheet Metal Without a Brake

Retrieved from: https://www.youtube.com/watch?v=iLEDaUUMf1I