*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate, I earn from qualifying purchases. Please read my disclaimer for additional details.

Clamps are versatile tools that you’ll find in construction, woodworking, and metalworking. These workshop tools hold materials in place for precise joining or cutting.

While all clamps perform the same function, there are many types of clamps.

Our detailed guide covers the common types of clamps available and their specific uses.

Table of Contents

32 Types of Clamps

Some of the most common clamp types include:

1. Table Clamps

A table clamp is a popular type of clamp that’s attached to a welding table.

The clamp allows for speedy one-handed clamping and is used for welding assemblies.

2. Quick Grid Clamps

A quick grid clamp is different from a quick release clamp.

These clamps make it easier to grip a work item quickly with one hand. Unlike most clamps, the quick grid clamp’s jaws are not very close to each other. This makes it ideal for using with thin items.

Their adjustable pressure also makes them versatile.

3. Bench Clamp

A bench clamp is handy when you need to screw down or hold pieces in place. These clamps are suitable when using a worktable.

Bench clamps are often used in welding, woodworking, and assemblies.

4. Cardellini Clamp

Cardellini clamps are designed for clamping onto round, square, or rectangular tubing. You can also use these clamps to clamp flat items.

The only downside is that these clamps are prone to damage when tightened too much. Their jaws press against each other when using them, and any tightening or quick adjustments can destroy the clamp.

5. Bench Vise Clamp

Bench vise clamps are great for drilling, sanding, and sawing, without worrying about the object shifting.

The bench vise clamp has a parallel and a fixed jaw. These jaws can be adjusted with a screw. You’ll also find portable types of bench vises that you can clamp or screw onto a workbench.

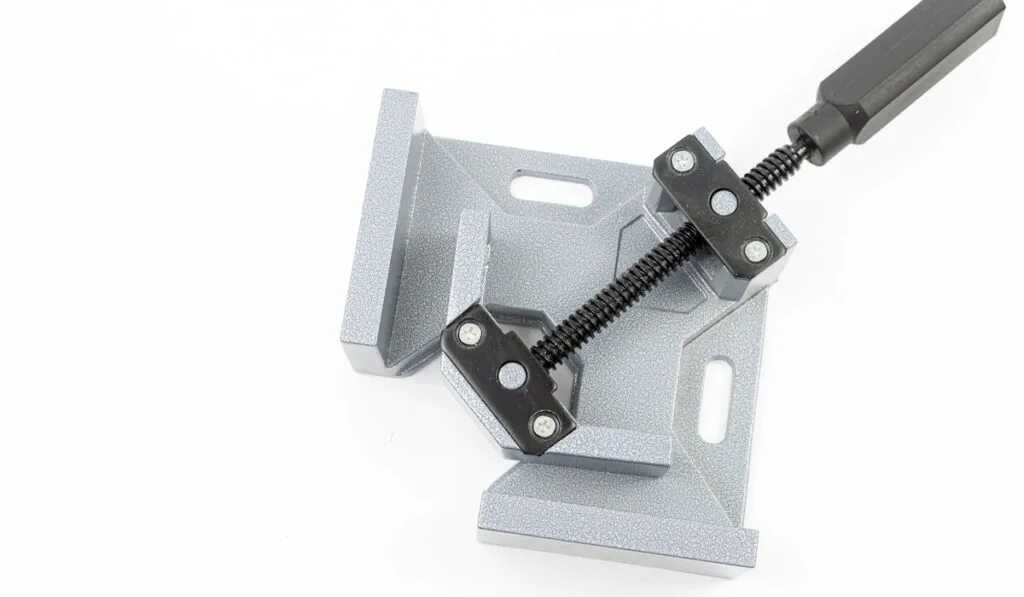

6. Corner Clamp

Corner clamps form a T-joint that allows you to hold your work in place.

Small corner clamps are great for picture frames. Once the frame is in place, you can glue and screw the separate parts together.

7. Dimide Clamps

A dimide clamp combines speed and power due to its compatibility with impact wrenches. It acts as a heavy-duty welding and metalworking clamp that prevents parts from slipping.

It also has a removable hex head and T-handle. That makes the clamp adjustable to fit in tight spaces. You can also use different drivers like torque wrenches, impact wrenches, and ratchets with the dimide clamp.

These clamps are suitable for any high-load clamping activities. It’s also the best tool if you’re looking for a clamp with extended reach capabilities.

8. Deep Throat Clamp

A deep throat clamp has a C-clamp’s deep reach and a bar clamp’s long width. The clamp can vary between 2 to 4 inches in depth and up to 70-80 inches long.

While you can use the deep throat clamp for various activities, it is ideal for woodworking, as it provides a firm grip with good pressure.

9. Drill Press Clamp

A drill press clamp has an adjustable and quick-release mechanism that allows you to grip boards and materials to a drill press table.

That allows you to make clean, accurate cuts. You can quickly put the material on the table and release it using a drill press clamp.

10. Edge Clamp

An edge clamp holds workpieces to an edge. Its three separate screws control the clamp’s two positions on two axes.

Edge clamps are suitable for welding, assemblies, and woodworking.

11. Step Clamp

Step clamps have serrations that allow you to tighten them in small steps. These clamps are mainly used on step blocks. The serrations provide excellent load bearing.

These steps fit together and create surface friction and resistance that prevent the clamp from slipping.

Step clamps are used together with step blocks to fix an item in place during milling.

12. Flooring Clamps

Flooring clamps have straps that pull two plates together. The curved edges on the plates hook onto the board’s end, and one has a ratchet that makes adjusting the strap tension easier.

These clamps come in handy when you need to laminate floorboards with interlocking joints or attach wooden panels.

13. G or C clamp

A G or C clamp gets its name from its shape. The clamp has a C-shaped frame and a long screw that goes through one end of the frame to create a G-like shape.

Its long screw adjusts the clamp’s jaw by pushing it towards the other jaw on the other frame’s end, which expands the space in between. You can use this clamp to hold a workpiece to the table or glue wood blocks together.

The frame’s size determines the size of the opening, which dictates the thickness of a workpiece that can fit inside the clamp.

There are different C-clamp designs ideal for metalworking and woodworking. Some of the standard designs include:

- Deep reach C-clamps – ideal for extended reach

- Double anvil C clamp – distributes load evenly

- Quick release C-clamps – quick-action

- Locking C-clamp – allows for one-handed use

- Standard C-clamp – common C-clamp design

14. Hand Clamp

Hand clamps are available in different styles and sizes.

Most hand clamps have a draw, bar, toggle, and parallel. They are commonly used in picture framing, bookbinding, and door making.

For example, the hand screw clamp is used in metalworking due to its strength. You can also use it to repair furniture after adjusting its jaws to fit angled materials.

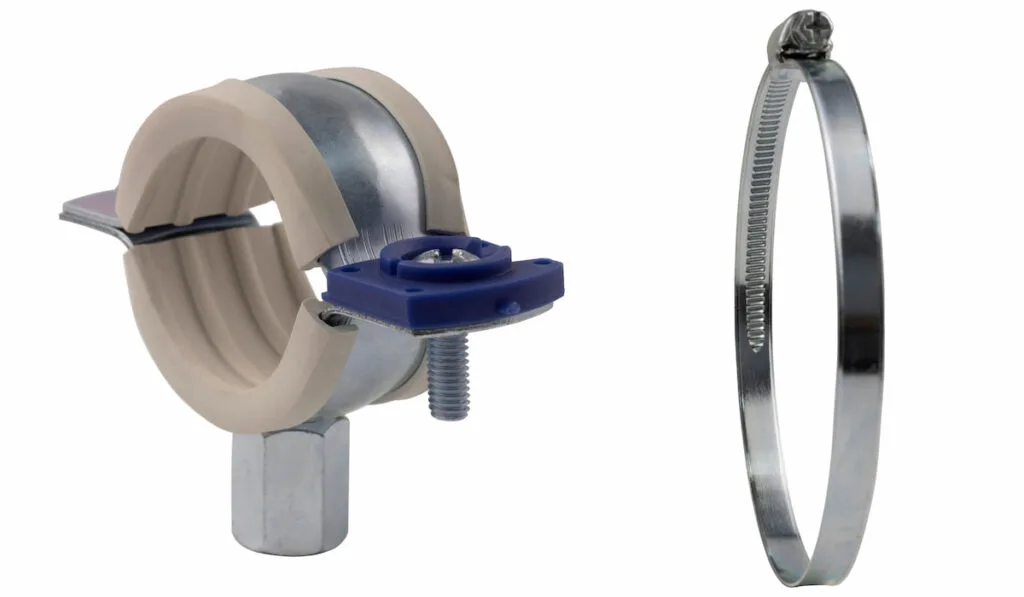

15. Hose Clamp

A hose clamp comes in different styles and types.

Unlike Marman clamps below, hose clamps do not exert much pressure, guaranteeing a better fix than duct tape.

Hose clamps are available in wire, ear, spring, and screw varieties. There are hose clamps designed for pipes. The clamp wraps around the ends and tightens to secure the hose to a pipe, spout, or nozzle.

16. Hydraulic Clamp

Hydraulic clamps use pressurized liquid to deliver a clamping load. These clamps work best for high-clamp loads, as they provide better control.

17. Kant Twist Clamp

The Kant twist clamp’s handle is positioned perpendicular to the clamp load. Its two parallel jaws deliver the load.

Its handle position prevents the clamp from twisting while being tightened.

Welders, metal workers, and woodworkers prefer the Kant twist clamp, as it can hold several workpieces together.

18. Locking Clamp

A locking clamp works like a sheet metal clamp. The only difference is that the locking clamp’s jaws have a larger surface area.

These clamps are ideal for metalworking, welding, woodworking, and when you can only use one hand.

Note that there’s also a locking chain clamp that works like a locking clamp. The only difference is that it has a chain clamp that allows you to apply a clamp load in a tight space.

The clamp applies pressure when the chain is tightened around an object. That allows it to clamp different shapes, and it’s widely used for metalworking.

19. Metal Clamp

Metal clamps are designed for heavy-duty jobs. The type of clamp you choose will determine its function, as different clamps have varying pressure.

Additionally, your physical strength and where you plan to use the clamp will determine what metal clamp you choose.

20. Miter Clamp

A miter clamp is designed to hold wood pieces with miter cuts.

When using a regular clamp in place of a miter clamp, you’ll notice that it exerts pressure that can cause the joints to slide away. A miter clamp pushes the miter joints towards each other and reduces any chance of sliding.

You only need to slide in the wooden item and tighten the screw to use the clamp.

There are miter clamps with moveable jaws and some with fixed right-angled clamp jaws. Miter clamps are ideal for assembling, holding wood edges/sheets, and other woodworking tasks.

21. Marman Clamp

The marman clamp is circular, similar to a band with a gap.

You can tighten or loosen the clamp with a metal bolt. Marman clamps are used to hold pipes or cylinders together. The clamp is sturdy, a reason it’s used in the aircraft industry.

22. Parallel Clamps

Parallel clamps’ jaws remain parallel under high loads, and their opening allows for large items. This type of clamp won’t leave dimples in wood.

These clamps are used for woodworking.

23. Quick Action Clamps

Quick action clamps are convenient, as you can use only one hand to operate them. That allows you to hold the item that needs clamping and the clamp itself.

Furthermore, you can use one finger to switch the fast release button, which provides fast movement. These clamps are versatile and can be used for single-handed jobs and woodworking.

24. Screw Clamps

Screw clamps are made of stainless steel, which makes them resistant to corrosion. These clamps are used to secure and surround hoses.

For example, the wood hand screw clamp has jaws that pivot to allow clamping at different angles. These clamps are ideal for woodworking.

25. Spring Clamp

A spring clamp, or pinch clamp, has two handles that connect to a jaw with a spring mechanism.

It’s a woodworking clamp used to hold wood pieces in place firmly. The clamp works similar to using pins on clothes.

Some carpenters insert padding between the wood and clamp when using a spring clamp to prevent wood damage. These clamps can also be used for minor repairs.

The spring clamp is your go-to tool when you need to apply pressure when working with wood. They have a similar force application to the large C-clamp and don’t stick out.

26. Sash Clamp

A sash clamp is similar to a pipe clamp. The only difference is that it has a flat bar, while a pipe clamp has a round bar.

It’s fitted with a fixed jaw-holder on one end. Twisting the long screw can also adjust the jaw. A sliding jaw can be moved along the rail along the bar’s length and locked into position to hold items in place.

Sash clamps are used to glue wooden blocks and boards together. The clamps provide a firm grip when working on tabletops, cabinets, and doors.

27. Speed Clamp

Speed clamps have one stationary side with a long bar. The part with the handle slides to make your work easier.

These clamps quickly move into a tight position, and the hand grip ratcheting adds to the convenience.

Speed clamps are common in the automotive industry, although they can be used in different projects.

28. Sheet Metal Clamps

A sheet metal clamp resembles locking clamps, but its clamp jaws have a more extensive surface area. That allows it to clamp sheet metal.

Its one-handed design is also convenient, especially when dealing with metalwork.

29. Toggle Clamp

A toggle clamp can be either right-angle, pull-, or push-type. The clamp is attached to a work surface to keep the material from moving.

Toggle clamps have slots for bolt or screw installation. After fixing the clamp, the work surface acts as the fixed jaw. Its handle also operates a clamping plate.

Once you push the handle down, force an adjusting screw onto the material to keep it in place.

These clamps are versatile and can be used in metalworking, woodworking, and drilling.

30. Pipe Clamp

Pipe clamps have a cylindrical shaft that wraps around the pipe. It also uses screws to tighten a pipe by providing a firm hold in different positions.

The clamp world likes the sash clamp, as it’s used in conjunction with pipes. It stretches over a wide area, which provides clamping pressure on wide items.

31. Web Clamp

Web clamps have nylon bands that wrap around an object and tighten using a ratchet. The nylon ensures that the item held doesn’t get damaged.

People working on frames use this clamp, as the pressure is distributed evenly, preventing any damage to the piece. Web clamps are also popular in woodworking.

32. Ground Clamps

Ground clamps are designed for electrical grounding, as they are highly conductive.

Final Thoughts

Although a clamp hardly comes to mind when thinking of valuable tools, it’s one of the most widely used and essential tools you can have in your workshop.

Our list has some of the most common clamp types and uses. Hopefully, you know which clamp to choose for your woodworking, lifting, metalworking, or welding project.

Resources

- https://wezaggle.com/types-of-clamps/

- https://www.woodworkingtrade.com/types-of-woodworking-clamps/

- https://dimide.com/blogs/why-dimide/clamp-guide-what-clamp-should-you-use-for-each-job

- https://www.thisoldhouse.com/house-one/21288420/clamp-guide

- https://worstroom.com/types-of-clamps/

- https://engineeringlearn.com/types-of-clamps-their-uses-with-pictures/’

- https://www.engineeringenotes.com/industrial-engineering/machine-tools/clamping-devices-rules-and-types-fixtures-machine-tools-engineering

- https://www.homestratosphere.com/types-of-clamps/

- https://www.bobvila.com/slideshow/get-a-grip-8-clamps-to-help-you-handle-any-project

- https://happydiyhome.com/types-of-clamps/