*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate, I earn from qualifying purchases. Please read my disclaimer for additional details.

Sizing the breaker for your air compressor correctly will save you a lot of headaches. Determine what size of breaker you need for your air compressor will help you troubleshoot issues, including overheating your machine or tripping your breaker.

What size breaker do I need for my air compressor? The breaker requirements for your air compressor depends upon the amperage rating of the motor in your air compressor. To determine what size breaker you need for your air compressor you will also need to look at the motor tag on your air compressor to find the voltage requirements.

In this guide, we have a section on how to calculate the size of breaker you will need for your air compressor. We have also included tips on how to prevent the overheating of your air compressor.

Table of Contents

Do Air Compressors Get Hot?

Air compressors can become subject to rapid fluctuations in temperature, including overheating or freezing depending upon ambient air temperature. Overheating can cause damage to an air compressor and shorten the lifespan of the system.

It is somewhat normal for a compressor to be on the hot side, since the act of compressing air generates a lot of heat. It’s good to know what to look for that will indicate the kind of heat that is too hot and verging on overheating.

Check out my article with 5 common reasons air compressors get hot for additional information.

What Causes Air Compressors To Get Hot?

There are several potential root causes for the overheating of your air compressor. Here we have included several of these causes of overheating to consider when you are troubleshooting your air compressor.

Air Temperature And Humidity

Surrounding air temperature has an appreciable effect on the internal operating temperature of the air compressor system. The ideal ambient air temperature range for air compressors is 50-85 degrees Fahrenheit, according to Fluid-Aire Dynamics, a supplier of air compressor parts.

Humidity also has an effect on the performance of air compressors. It is best for air compressors to operate in dry, low humidity conditions because this means there will be less condensate within your air compressor. As a result, there will be less moisture to remove from the air compressor.

Here are some recommendations if you have no choice but to operate your air compressor in air temperatures regularly exceeding 85 degrees:

- Ensure Proper Ventilation

- Make sure that there is a supply of fresh, cooler air to the space containing the air compressor

- This can be simple as an open window or door to let in fresh air

Avoid Blocking Air Compressor Ventilation Openings

Air compressors contain ventilation openings that help regulate the internal temperature of the machine. It is critical for operator safety to make sure that the ventilation openings on your air compressor are not blocked.

Voltage And Circuit Protection

Your air compressor can be at risk of overheating due to a lack of voltage and circuit protection.

Select air compressors can be operated on a 15-amp circuit as long as the following safeguards are put in place:

- The voltage supply to the circuit needs to meet the National Electrical Code.

- The circuit is not being used to supply power to any other items

- Any extension cords used must meet specifications listed in the specifications chart of the user manual for the air compressor

- The circuit has been equipped with either a 15-amp circuit breaker or a 15-amp time delay fuse

Dirty Cooling Surfaces

Cooling surfaces that have accumulated dust and filth can contribute to the overheating of the air compressor.

Clean all surfaces on the pump and motor thoroughly to ensure that dust and grime do not accumulate over time, blocking cooling vents. Your user manual should provide information on how to do this.

A Leaking Safety Valve

A leaking safety valve can also contribute to the air compressor overheating, since the system is not adequately keeping the tank pressurized.

Replace the worn parts. You can reassemble parts using plumber’s tape , or whatever method is recommended by your air compressor’s user manual

How to Prevent an Air Compressor From Getting Hot

Here you will find the remedial steps we recommend taking if you encounter issues related to the overheating of tour air compressor.

Avoid Blocking Ventilation Openings

The safety manual for the 6 gallon pancake air compressor states the following regarding the ventilation openings on the air compressor:

“Restricting any of the compressor ventilation openings will cause serious overheating and could cause fire.”

It is further recommended that you:

- Never place objects either on top of or against your air compressor

- Do not operate the air compressor within a confined space such as a closed garage

- Keep the air compressor at least 12 inches from a wall or any other object that may interfere with the air ventilation process

Ensure Proper Voltage And Circuit Protection

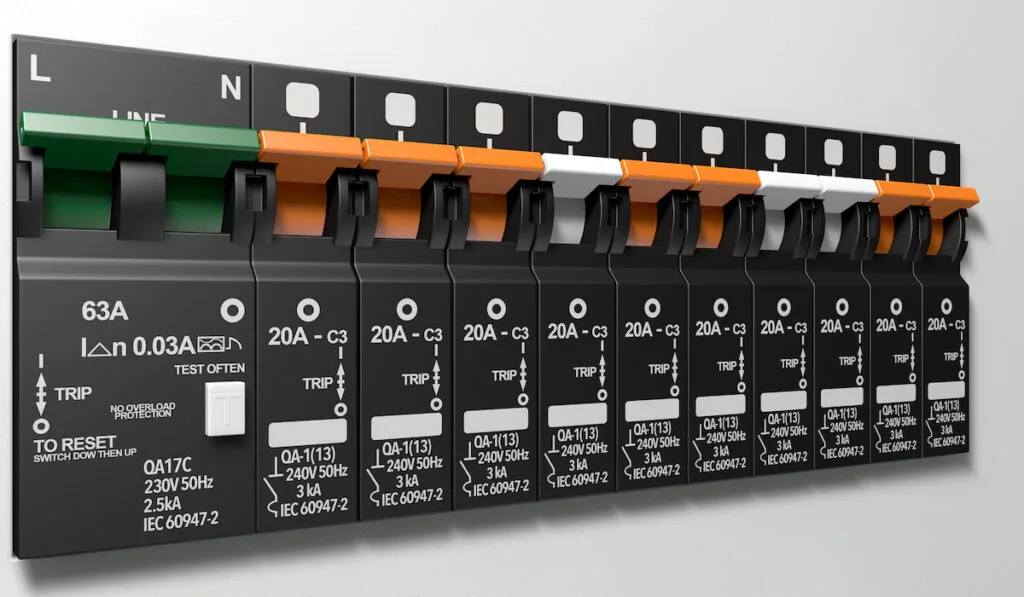

Air compressors have circuit breakers to protect the air pump and compressor when there is a fault in the electrical system. Having an improperly sized circuit breaker or time delay fuse can lead to a risk of overheating, according to the safety manual linked above.

For example, if you happen to have an air compressor that operates on a 15-amp circuit, you will want to make sure you have a 15-amp circuit breaker .

If your air compressor is connected to a circuit protected by fuses, use only time delay fuses. Time delay fuses are denoted by the symbol “T” in the United States.

An example of a time delay fuse for an air compressor operating on a 15-amp circuit is this 15A Slow Blow 15 Amp Time Delay Fuse .

Sizing A Circuit Breaker For An Air Compressor

If your air compressor is not fitted with the correct circuit breaker, it will be subject to random tripping while you are trying to get a job done.

Circuit breakers are sized by their amperage ratings, while the motors in air compressors are sized by horsepower, as is the case with this Stealth Ultra Quiet 0.5 HP Air Compressor .

You need to have a knowledge of the electricity formulas in order to determine the amperage requirements for your air compressor, given the horsepower rating of the engine in your air compressor.

Here are the steps to make this calculation:

- First convert horsepower to watts, 1 HP is equivalent 745.7 Watts, according to the University of Washington

- Multiplying the 0.5 HP rating of The Stealth Ultra Quiet Air Compressor by 745.7 Watts yields a result of 373 watts of power being consumed.

- Breakers are sized by amperage, referred to as ampacity. Multiplying the voltage and amperage yields watts of power.

- You can read the tag on the motor of your system to determine the voltage requirements of your air compressor.

- The voltage requirements of the stealth system is 120 volts

- Divide 373 watts by 120 volts to yield 3.11 amps

However, you cannot size your circuit breaker up to the running current draw of 3.11 amps. Motors draw more power during start-up than they do while they are running.

If you are manually making changes to the circuit breaker system in your air compressor you are should be consulting with a qualified electrician.

Still, it is always beneficial to learn how to properly size a circuit breaker in your air compressor so that you can properly communicate your issues with qualified technicians.

This information also helps you troubleshoot overheating issues associated with your air compressor system.

Rodger

Saturday 10th of July 2021

Kobold 3.5 running hp 16 amps