*This post may have affiliate links, which means I may receive commissions if you choose to purchase through links I provide (at no extra cost to you). As an Amazon Associate, I earn from qualifying purchases. Please read my disclaimer for additional details.

When you have the right hammer, everything starts to look like a nail, or so the saying goes.

There are many distinct types of hammers, so choosing one will depend on what you’re doing and how fast you want to get things done.

A quality hammer is the foundation of every good toolkit.

It would be best to start with a basic hammer that’s made well and large enough to manage most home projects.

Then, once you start moving into other areas of work, you can begin buying specialty hammers designed for a specific task.

There are also hammers you’ll have to hire someone to use.

For example, not everyone will have a jackhammer in their garage. You’ll probably require professional support if you’re working on concrete or building a new sidewalk.

We’ve put together a list of eleven of the most common types of hammers you’ll see to help you know what you need for your next repair or renovation.

Table of Contents

Claw Hammer

A claw hammer is what most people likely have sitting in their sheds or toolboxes.

It’s the prototypical hammer head on one end and a claw on the other side of the head that pulls out nails. The claw comes in handy all the time.

You can pry apart wooden boards with them, break apart old drywall, or even draw lines in drywall panels to cut them to size.

When built correctly, the claw also offers good weight stability for hammer swings, making getting nails into stubborn materials much more manageable.

When 99% of people ask to borrow a hammer or want to buy a hammer, they’re talking about claw hammers.

Anytime you need something different, you’ll want to add whatever type of hammer you’re looking for to your request.

Framing Hammer

The framing hammer looks much like a claw hammer, but you’ll notice subtle differences in shape and weight.

Framing hammers are what construction workers typically use when building wooden frames in new construction.

The hammer end is heavier and more robust than on a normal claw hammer, and the claw is usually higher up and straighter.

The design gives framers more strength with every swing. They don’t need a curved claw because they frame every day and make fewer mistakes, so they’re not pulling as many nails.

Instead, the hammer emphasizes power in the hammer end to quickly drive nails into beams.

Ball Peen Hammer

Ball peen hammers are what engineers and machinists use when they need to round edges on fasteners, aluminum sheets, and other metal surfaces.

The rounded shape of the ball peen avoids dents in the metal and instead gives them a nice, rounded look.

All it takes is several light taps from the ball peen to get rid of sharp or out-of-place edges.

Other than that, however, a ball peen hammer looks much like a standard claw hammer.

For most people, it will still do the trick at home if you’re hanging pictures or need to nail a cabinet together. You just won’t be able to pull any nails out if you mishit.

Sledgehammer

When something needs breaking, a sledgehammer is up to the task. These aren’t your normal-sized hammers, though some sledgehammers come in smaller shapes.

They’re much heavier than typical hammers because they’re designed to break through hard surfaces.

You can use a sledgehammer to break through walls, break up concrete, or smash an old toilet down to size so it fits in your garbage bin.

A sledgehammer is a fantastic tool to have in the garage or the shed when you need to break something.

Rubber Mallet

Rubber mallets are a type of hammer people use when they need to hammer delicate objects.

Usually, each end of the mallet is made of rubber or some other soft material that won’t dent or break whatever it’s hitting.

Instead, the force of the swing comes back toward whoever is using the hammer.

Rubber mallets are best used by tapping delicate or fragile items softly.

For example, they’re perfect for tapping small pieces of conjoined wood into place or working with marble countertops when a regular hammer will chip, dent, or scratch the surface.

Dead Blow Hammer

The dead blow hammer gets its name because the design limits the recoil of swings.

Artisans and craftspeople use dead blow hammers when they need to swing a hammer in a tight space and worry about damaging other things around where they’re swinging.

For example, putting nails in corners is a challenge if you’re making a custom cabinet. If you use a regular hammer, the recoil will likely end up scratching the walls or doors of the cabinet.

A dead blow hammer lets you hit nails without significant recoil, so you can place nails in tight spaces.

Welding Hammer

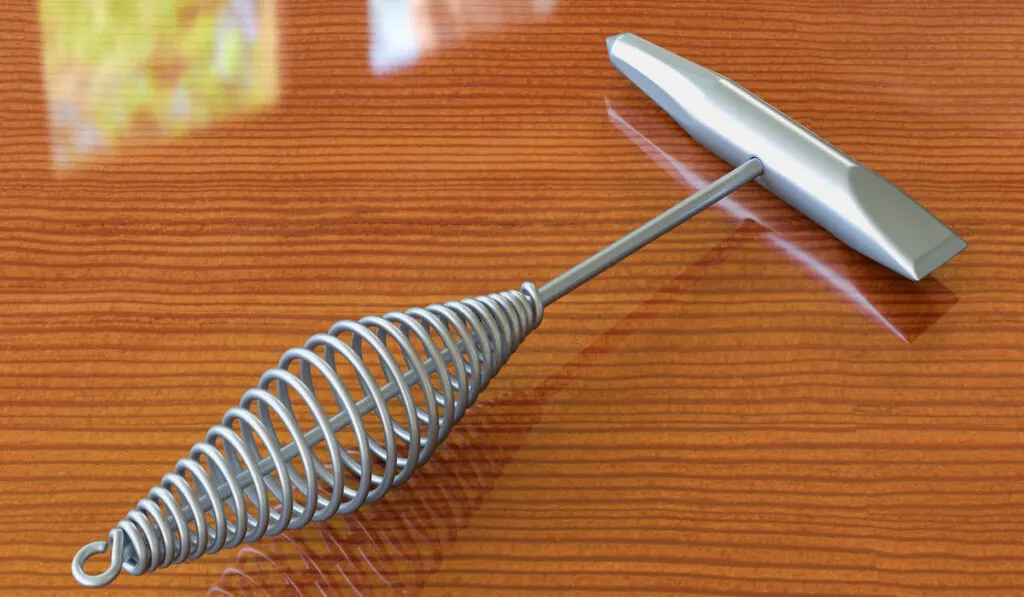

A welder’s hammer has one of the most unique designs on this list.

Typically, the hammerhead has both a sharp end with a long edge, and the other side of the head is pointed. The handle is made of coiled metal.

Welders use these hammers to get rid of waste when they’re working. They chip away any extra materials around the welding point before things cool.

While it looks cool, this isn’t something most people will ever buy. Instead, it’s a specialty tool that only welders need.

Rock Hammer

Rock hammers are much smaller than regular hammers. Geologists use them to break up small rocks bit by bit to avoid damaging gems and other things they research.

Some people call these geologists hammers, but most people know them as rock hammers.

You won’t want to have one of these in your toolbox for any home projects, but you may want to grab one if you’re out having some fun exploring with kids in the yard or are into rocks as a hobbyist.

Electrician Hammer

Electrician hammers have a longer neck than other types of hammers to help electricians reach areas inside walls or behind beams that are hard to get to.

In addition, the extended neck gives them power in their swing in tight spots where they may not have as much room to swing their arms.

Other than that, there’s not much difference between a regular hammer and an electrician hammer.

They may have a rubber handle to lower the risk of electrocution, but an electrician’s hammer will also double nicely as your everyday hammer.

Brick Hammer

Brick hammers usually have a square flat end on one side and what looks like a chisel claw on the other.

Masons use brick hammers to score bricks, and they can also split bricks when necessary. These are also frequently called mason hammers.

Drywall Hammers

A seasoned contractor will use almost any edged hammer to cut and shape drywall panels, but specialty hammers are designed for that purpose.

A drywall hammer has a regular flat hammer head on one side, but the other is a sharp-edged tool that slices down drywall panels for simple cuts.

Conclusion

Finding the right type of hammer makes work progress much faster.

While most people will only need one or two hammers for home repairs and regular tasks, larger renovations are easier using specialty hammers.

Thankfully, most of the hammers on this list are affordable, so buying them won’t put you out much.

Instead, you’ll be glad you have them when you want to save time and avoid damaging whatever it is you’re working on.